Wonder CVD

Wonder CVD

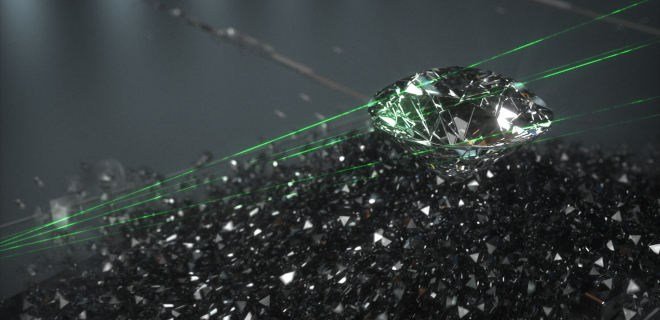

We are the pioneers of lab-grown diamonds.

We are changing the market and consumption culture with our groundbreaking technology and industry expertise.

Sustainability

We respect the planet, communities and the world around us.

Our approach is radical disruption of status quo through invention of new greener and smarter technologies. We are challenging and redefining the market, making our statement in this rapidly changing world.

Our production process involves lower levels of carbon emissions, water and energy usage with no labour exploitation and no land disruption.

Each diamond is made in a state-of-the art facility by brilliant scientists passionate about every detail of the process.

Vision

Luxury

We are perfectionists with deep appreciation of authentic luxury.

A diamond has historically been a symbol of quality, exclusivity, privilege and beauty. As the modern definition of luxury evolves towards consciousness and responsibility,

it is no longer enough for a diamond to be just an image of aesthetics and social status. It needs to reflect the inner values.

More about CVD diamond on www.wonderdiamond.com

Disruptive Innovation

We believe it is possible to have it all without sacrificing your values.

Our laboratory-created diamond combines quality, authenticity, sustainability and innovation. It is a modern luxury free from compromises.

Join us in our mission to revolutionise the industry, creating a more authentic, sustainable, and inclusive future.

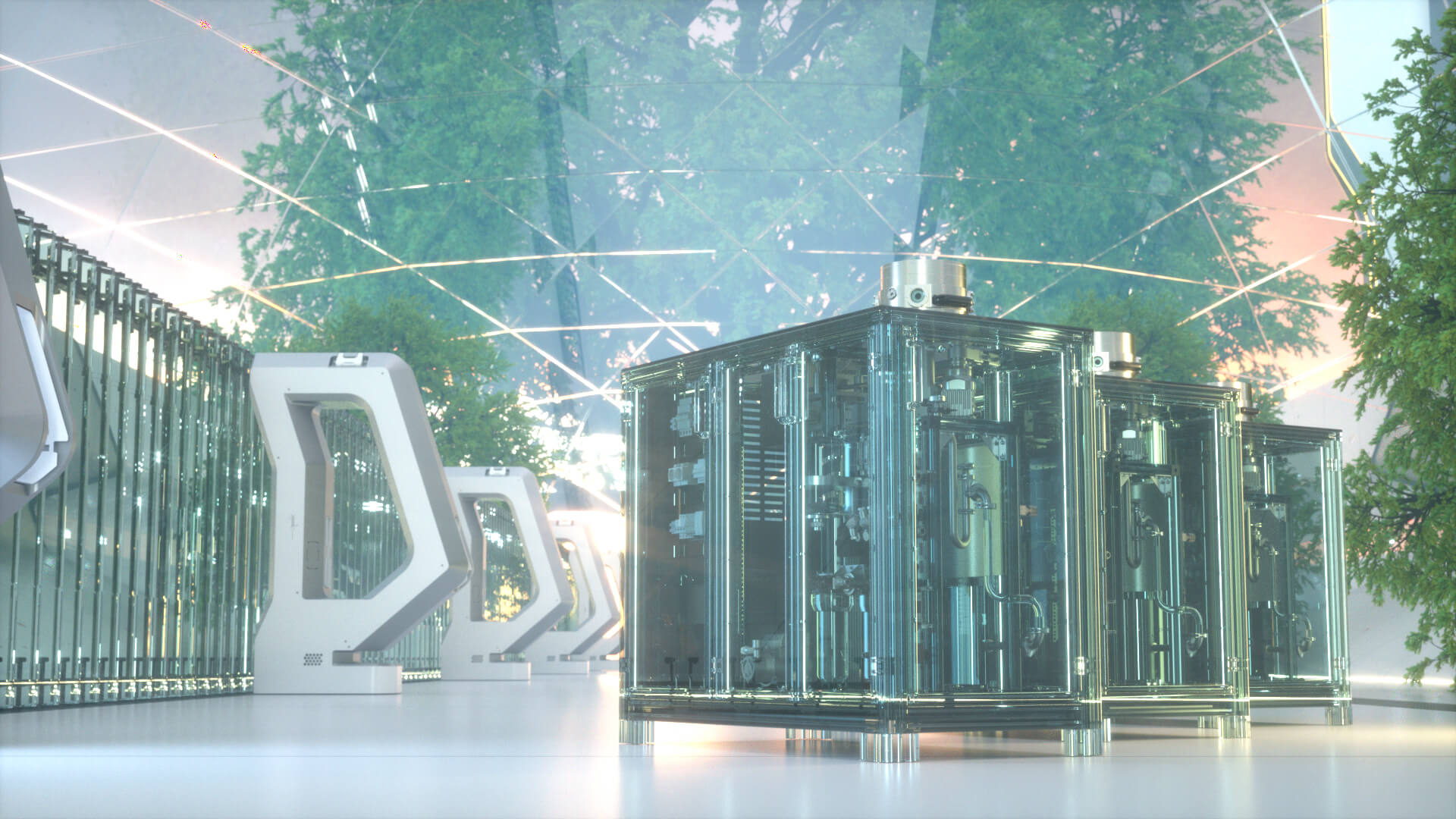

Turnkey diamond growth solution

We have all elements of value chain in-house, from R&D to industrial production:

Production of high-quality reactors in UAE

Diamond growth technology

Qualified engineering and R&D team

Сustomized investment project tailored for your needs

Customized project includes:

Feel free

to contact us

We look forward to discussing your needs, design and support your project from A to Z

Contact us

Boulevard Plaza Tower 2 Dubai UAE P.O. Box 418695 Dubai +971 52 7559100

Contact us

Boulevard Plaza Tower 2 Dubai UAE P.O. Box 418695 Dubai +971 52 7559100